Push Vs Pull System Examples . The difference between push and pull systems relates to when production occurs. This eventually helps to reduce waste and improve quality. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. It also allows for more accurate forecasting and planning of production runs. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product. The product is pushed out in a push system based on.

from bitrebels.com

Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that. The difference between push and pull systems relates to when production occurs. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product. The product is pushed out in a push system based on. This eventually helps to reduce waste and improve quality. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. It also allows for more accurate forecasting and planning of production runs.

Push vs. Pull System Understanding The Basics And How It Affects Your

Push Vs Pull System Examples Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that. Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that. The product is pushed out in a push system based on. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product. It also allows for more accurate forecasting and planning of production runs. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. The difference between push and pull systems relates to when production occurs. This eventually helps to reduce waste and improve quality.

From www.dozuki.com

Push vs. Pull System in Manufacturing A Complete Overview for Push Vs Pull System Examples Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product. The difference between push and pull systems relates to when. Push Vs Pull System Examples.

From slidemodel.com

Manufacturing Pull vs Push PowerPoint Template SlideModel Push Vs Pull System Examples The product is pushed out in a push system based on. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. The difference between push and pull systems relates to when. Push Vs Pull System Examples.

From www.slideserve.com

PPT Push and Pull Production Systems PowerPoint Presentation ID385010 Push Vs Pull System Examples Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. This eventually helps to reduce waste and improve quality. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. Companies use push systems. Push Vs Pull System Examples.

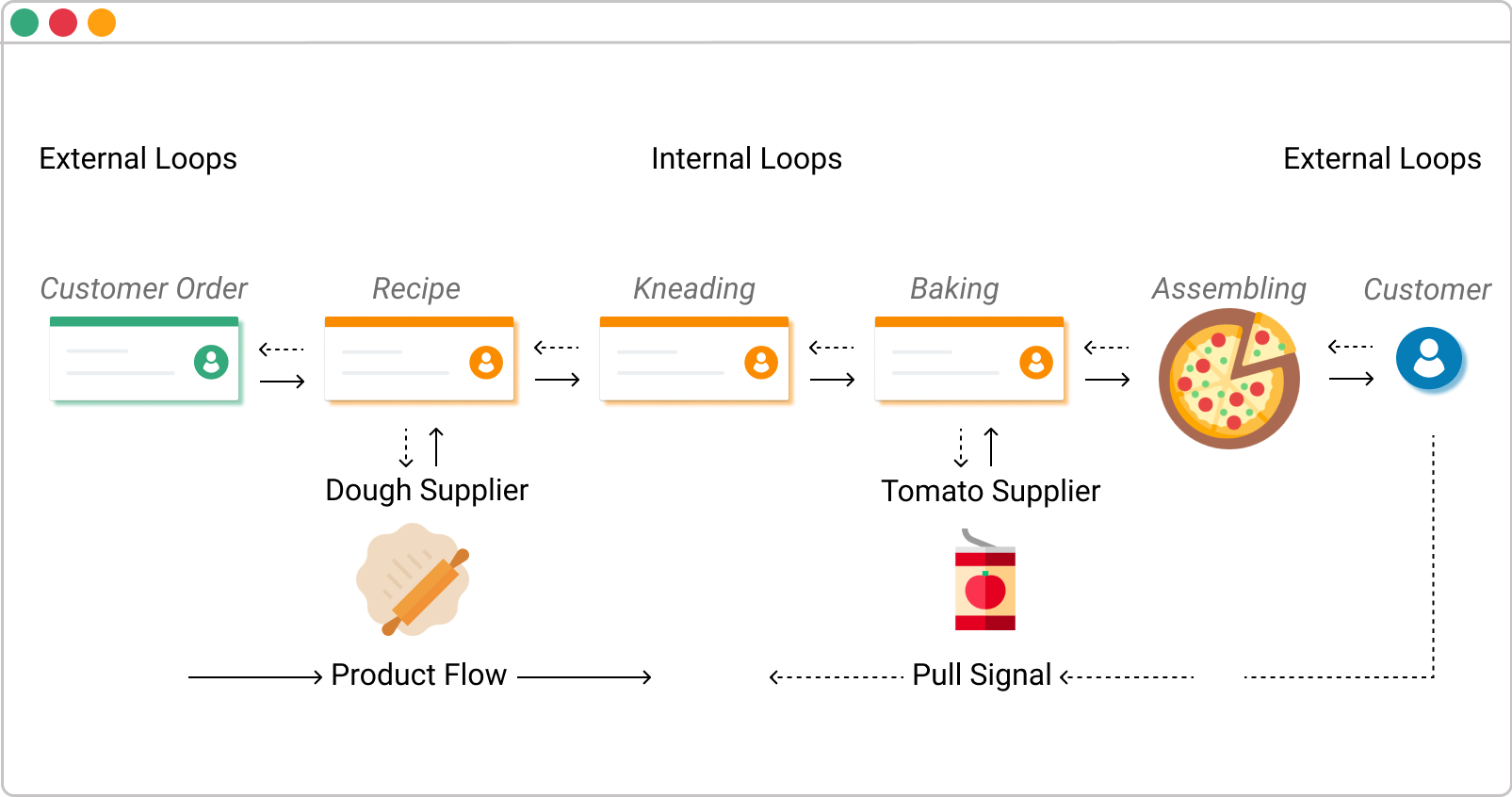

From kanbanize.com

What Is a Pull System? A Practical Guide to Increasing Process Efficiency Push Vs Pull System Examples The product is pushed out in a push system based on. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. This eventually helps to reduce waste and improve quality. Companies. Push Vs Pull System Examples.

From www.slideshare.net

Pull Systems Push Vs Pull System Examples It also allows for more accurate forecasting and planning of production runs. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of. Push Vs Pull System Examples.

From www.cyberclick.net

Push and Pull Strategies What They Are and Examples Push Vs Pull System Examples The difference between push and pull systems relates to when production occurs. It also allows for more accurate forecasting and planning of production runs. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. The product is pushed out in a. Push Vs Pull System Examples.

From operationsinsider.com

Push vs Pull — Operations Insider Push Vs Pull System Examples The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product. It also allows for more accurate forecasting and planning of production runs. The product is pushed out in a push system based on. Companies use push systems when there is a high demand for specific products and plenty of. Push Vs Pull System Examples.

From powerslides.com

Push vs Pull Strategy 7,000+ Templates PowerSlides™ Push Vs Pull System Examples The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product. This eventually helps to reduce waste and improve quality. Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that. It also allows for more accurate forecasting and. Push Vs Pull System Examples.

From blog.megaventory.com

Push vs Pull Inventory Management Which One Is Better For You Push Vs Pull System Examples It also allows for more accurate forecasting and planning of production runs. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of. Push Vs Pull System Examples.

From ideas.iwmarketing.com

Push vs. Pull Marketing Strategy What's Right for Your Business? Push Vs Pull System Examples Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that. It also allows for more accurate forecasting and planning of production runs. The difference between push and pull systems relates to when production occurs. This eventually helps to reduce waste and improve quality. In lean manufacturing, push system. Push Vs Pull System Examples.

From www.inflowinventory.com

Push vs Pull System Manufacturing An InDepth Analysis Push Vs Pull System Examples The product is pushed out in a push system based on. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. This eventually. Push Vs Pull System Examples.

From mavink.com

Push And Pull System Push Vs Pull System Examples Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that. The main difference between push and pull manufacturing is. Push Vs Pull System Examples.

From www.slideserve.com

PPT Supply Chain Management PowerPoint Presentation, free download Push Vs Pull System Examples Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that. It also allows for more accurate forecasting and planning. Push Vs Pull System Examples.

From powerslides.com

Push vs Pull Strategy 7,000+ Templates PowerSlides™ Push Vs Pull System Examples This eventually helps to reduce waste and improve quality. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that.. Push Vs Pull System Examples.

From elsmar.com

Push vs. Pull Push Vs Pull System Examples Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. The product is pushed out in a push system based on. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. This eventually. Push Vs Pull System Examples.

From www.impactfirst.co

Pull System Definition, Its 3 Types & Differences with Push Push Vs Pull System Examples Companies use push systems when there is a high demand for specific products and plenty of supply is available to meet that. The difference between push and pull systems relates to when production occurs. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product. This eventually helps to reduce. Push Vs Pull System Examples.

From www.blockchain-council.org

What is Push and Pull Strategy in Supply Chain Management? Push Vs Pull System Examples The difference between push and pull systems relates to when production occurs. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. The product is pushed out in a push system based on. The main difference between push and pull manufacturing. Push Vs Pull System Examples.

From dev.powerslides.com

Push vs Pull Strategy 7,000+ Templates PowerSlides™ Push Vs Pull System Examples This eventually helps to reduce waste and improve quality. Explaining the difference between push and pull in lean six sigma, and why the goal in a lean process is to “flow value at the pull of the customer”. The difference between push and pull systems relates to when production occurs. In lean manufacturing, push system vs pull system represent the. Push Vs Pull System Examples.